![]()

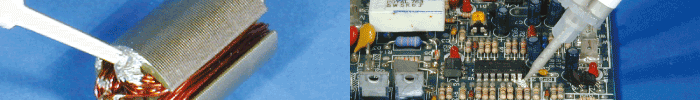

High Temperature Epoxies for Bonding and Filling to +340ºC

Duralco™ High Temperature Epoxies are unique, cross linked, organic-inorganic polymer systems

designed for use from -55ºC to +340ºC. They offer excellent adhesion, high temperature stability, dielectric properties and superior chemical, corrosion and moisture resistance. They are ideal for assembly, castings, tooling, repairs and bonding. Widely used in high performance motors, instruments, pumps, appliances, electronics,

semi-conductors, production applications. Choose from room temperature curing, coating and impregnating,

high thermal conductivity, potting and casting grades. For applications involving a continuous use temperature above

340ºC choose from the range of ceramic adhesives.

Download PDF selection guide for High Temperature Epoxies Properties

Electrically Conductive

Conductive adhesives and potting compounds provide the conductivity required for many high temperature electronic and industrial applications. They will bond to glass ceramics, metals and plastics, offering excellent resistance to most chemicals and solvents. Applications include solder replacement, semi-conductor bonding, shielding electronics and circuit repair.

Download the PDF for

Electrically Conductive Overview

Thermally Conductive

Thermally conductive adhesives and potting compounds provide the heat dissipation required for many high temperature electronic and industrial applications. These ultra temperature adhesives combine a unique polymer system and specially thermally conductive fillers rto provide continuous service up to +340ºC.

Download the PDF for

Thermally Conductive Overview

Adhesives, Fillers and Coatings

Range of high temperature epoxies to provide a solutions including;

Electrically resistant | Super flexible | Low viscosity | Tooling compound | Mix and apply, castable and machinable epoxies.

Download the PDF for

High Temperature Epoxies Overview

Potting Compounds

Range of high temperature epoxies to provide solutions including;

Low Viscosity Impregnant | High Temperature Low Viscosity | Flexible Low viscosity | Thermally Conductive | Thermallly Insulating.

Download the PDF for

Potting Compounds Overview

For further information please see either the PDF links above, or for additional assistance please contact us:

USA Sales: Phone us on +1 (317) 244 6643 or email us at usasales@rayfast.com

UK/Europe Sales: Phone us on +44(0) 1793 439144 or email us at uksales@rayfast.com

For guidance on installation procedures please see PDF download Installation Instructions

Authorised Distributor for TE Connectivity

Raychem Wire, Harness, Protection & Identification Products

Terms & Conditions | GDPR | Privacy Policy | Trademarks & Disclaimer | Sitemap | Download Adobe