![]()

High Temperature Ceramic Adhesives, Fillers & Coatings up to +3000ºC

Resbond® High Temperature Ceramics speciality adhesives will bond to ceramics, metals, glass and plastics etc. for research, electronics, metallurgical, nuclear and industrial applications. They offer excellent high temperature stability, dielectric strength, mechanical properties and thermal shock resistance. They are resistant to molten metals, oxidising and reducing atmospheres, as well as most chemicals and solvents.

Resbond® adhesives are based on high purity ceramic binders and selected powders. They are easily cured at room temperature without objectionable odours or outgassing. Available in a wide range of viscosities, strengths, conductivities, expansion rates and dielectric strengths. Resbond® adhesives are designed to satisfy the most difficult application requirements.

Download PDF selection guide for High Temperature Ceramics Properties

Range of Adhesives and Fillers

A comprehensive range that includes;

Electrically Resistant | Thermally Conductive | High Expansion | Single Component | Fireproof Adhesive, Sealant, Putty | Low Expansion Adhesive | Fast Setting Adhesive | Zirconia Adhesive and Coating | Electrically Conductive Adhesive | Metallic Adhesives

Download the PDF for

Ceramic Adhesives Overview

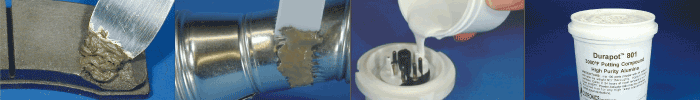

Ceramic Putties and Potting Compounds

A comprehensive range that includes;

Aluminium Putty | Stainless Steel Putty | Alumina Potting Compounds | Electrically Resistant Cement | High Speed Potting Cement | Low Expansion Cement

Download the PDF for

Ceramic Putty and Potting Overview

For further information please see either the PDF links above, or for additional assistance please contact us:

USA Sales: Phone us on +1 (317) 244 6643 or email us at usasales@rayfast.com

UK/Europe Sales: Phone us on +44(0) 1793 439144 or email us at uksales@rayfast.com

. For guidance on installation procedures please see PDF download Installation Instructions

Authorised Distributor for TE Connectivity

Raychem Wire, Harness, Protection & Identification Products

Terms & Conditions | GDPR | Privacy Policy | Trademarks & Disclaimer | Sitemap | Download Adobe